AQS Baden-Württemberg

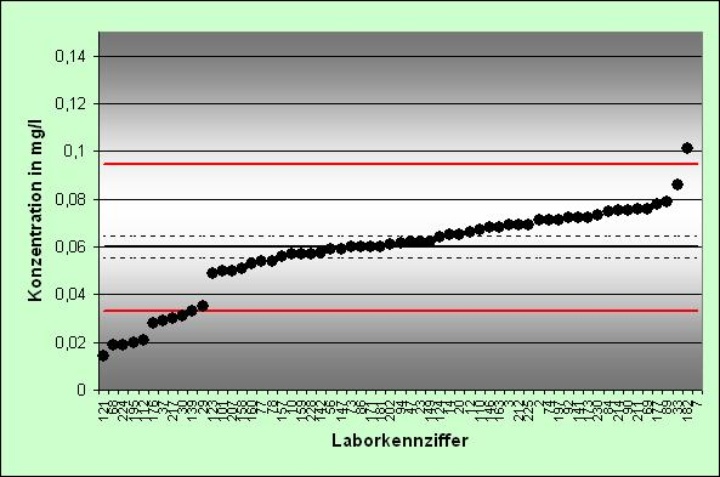

Das Institut für Siedlungswasserbau, Wassergüte- und Abfallwirtschaft führt unter dem Namen AQS Baden-Württemberg diverse Aktivitäten zu Qualitätssicherung in chemisch-analytischen Laboratorien durch. In erster Linie sind das Eignungstest-Ringversuche (hauptsächlich auf dem Gebiet der Wasseranalytik) und Lehrgänge für Laborpersonal. Daneben organisiert die AQS Baden-Württemberg gelegentlich auch Validierungsringversuche für neue Verfahren in der Wasseranalytik im Zuge der Normung durch ISO, CEN und DIN. Auf Wunsch werden auch individuelle Eignungsprüfungen angeboten, die Laboratorien im Rahmen der Akkreditierung nach DIN EN ISO/IEC 17025 benötigen.

Lehrgänge der AQS Baden-Württemberg

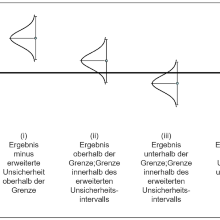

Die AQS Baden-Württemberg führt regelmäßig Lehrgänge zur Probenahme von Abwasser, zum Führen von Qualitätsregelkarten und zur Abschätzung der Messunsicherheit durch, ggf. auch als Inhouse-Schulungen.

Neuigkeiten AQS

Aktuelle Tipps:

- Die LAWA AQS-Merkblätter sind jetzt auf der Webseite der LAWA kostenfrei verfügbar.

- Eurolab-D "Kochbuch"-Dokumente. Informelle Dokumente, die Laboratorien eine Hilfestellung bei der Umsetzung der Norm DIN EN ISO/IEC 17025 bieten sollen. Schauen Sie mal rein.

- Eurachem guidance documents and information leaflets on a range of issues in quality and accreditation for analytical measurement - teilweise auch auf deutsch

- Eurachem reading list - welche Dokumente sind für die Qualitätssicherung in der Analytik wichtig?

Kontaktadresse

AQS Baden-Württemberg

Institut für Siedlungswasserbau, Wassergüte- und Abfallwirtschaft

Arbeitsbereich Hydrochemie und Analytische Qualitätssicherung

Bandtäle 2

70569 Stuttgart

Deutschland

Tel.: +49(0)711 685-65446

Fax: +49(0)711 685-55446

E-Mail: info@aqsbw.de

Ihre Ansprechpartner

Michael Koch

Dr.-Ing.Wissenschaftlicher Leiter AQS Baden-Württemberg (LFL / AQS)

Frank Baumeister

Dr.-Ing.Technischer Leiter AQS

Mirela Kordic

Sekretariat AQS